This is the real Porter, who counts several common material transportation methods < br / >

If we talk about how to transport materials from one place to another, there are more choices now.

Whether it is particles, powder, liquid or gas, there are corresponding handling equipment, the following to understand the main material delivery mode.

The development history of transportation

At first, human beings used both hands to carry objects. Later, they began to use simple tools and many people to carry objects. For example, many people used ropes and sticks to carry objects, and rolling objects on logs.

Later, humans began to learn to use natural resources to provide energy for long-distance transportation of objects, such as water and wind.

In the 19th century, with the advent of industrial revolution and new technology, a large number of conveying equipment appeared, which not only reduced the labor intensity, but also improved the efficiency of material handling.

As we are familiar with the belt conveyor, screw conveyor and steel belt conveyor, all appeared in the mid-19th century.

With the development of technology and materials, the objects to be transported become diverse, such as gas, liquid and so on. The transportation distance has also changed from the workshop to the city to the city, even between the country, and the transportation equipment has become an indispensable equipment in the society.

Let's take an inventory of the common material transportation methods < br / >

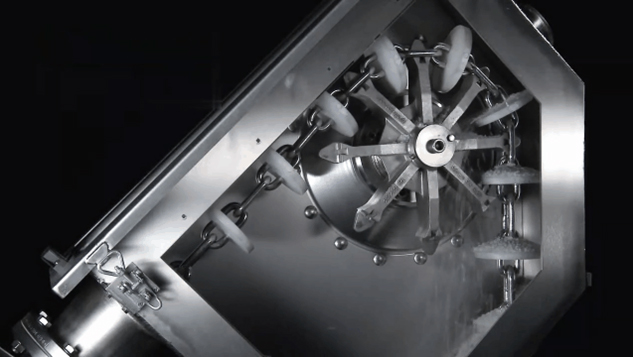

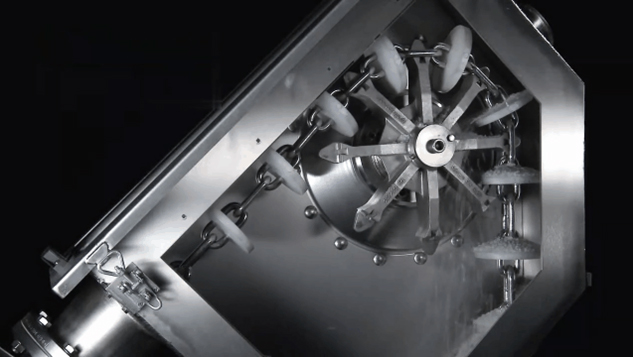

Screw conveying < br / >

Spiral conveying is the use of motor driven screw rotation, moving materials to achieve the purpose of conveying materials, it can be horizontal, inclined, vertical or even any combination to transport materials.

The spiral feeding system is mainly composed of material trough, spiral blade, rotating shaft and driving device.

Spiral conveying is mainly used for conveying various powder, granular and small materials; it is widely used in grain industry, building material industry, chemical industry, machinery manufacturing industry, transportation industry and other industries.

When the screw body rotates, the material entering the material trough is pushed by the direction of the rotating blade, which makes the material rotate around the axis with the rotation of the blade, so as to realize the purpose of conveying materials. Screw conveyor can be used with all kinds of extruders and high-speed mixers to realize automatic feeding.

Conveyor belt < br / >

Conveyor belt, also known as conveyor belt, is a rubber fiber, metal composite products, or plastic and fabric composite products belt to carry and transport materials, the bottom of the belt or chain drive roller rotation, thus driving the belt to transport materials.

Conveyor belt is widely used in agriculture, industrial and mining enterprises and transportation industry to transport various solid block and powder materials or finished articles.

Conveyor belt can be continuous, high efficiency, large angle transportation, conveyor belt operation safety, easy to use, easy maintenance, low freight, and can shorten the transportation distance, reduce the project cost, save manpower and material resources.

Pipeline transportation < br / >

Pipeline transportation is mainly used to transport gas or liquid with long distance and large diameter or short distance and small diameter, which is one of the most important equipment in petrochemical and natural gas industries.

Compared with other transportation modes, pipeline transportation has the characteristics of large volume, good airtightness, low cost and high safety factor.

Pipeline transportation can be divided into isothermal transportation, heating transportation and sequential transportation according to the transportation process; according to the transportation medium, it can be divided into crude oil pipeline, product oil pipeline and natural gas pipeline.

The development of pipeline transportation is closely related to the development of energy industry. With the increasing use of fossil energy by human beings, the pipeline of energy transmission will be laid farther and farther.

Compared with other modes of transportation, pipeline transportation has the following characteristics: firstly, the pipeline transportation volume is large, compared with railway transportation, the infrastructure cost is low; it is less affected by climate and other factors, and can operate stably and continuously for a long time, with less pollution to the environment; with low transportation price and less energy consumption, the pipeline transportation price is about one fifth to one sixth of that of railway, which is only higher than that of waterway transportation; it is less restricted by terrain, and basically No cultivated land is occupied.

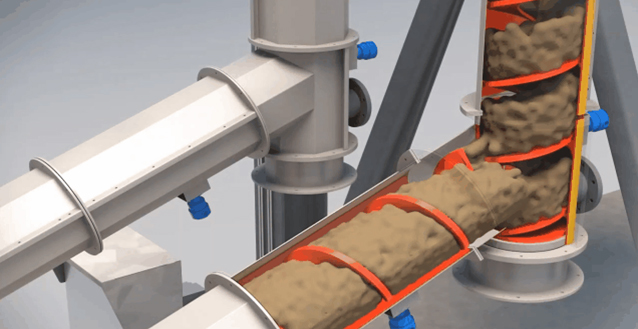

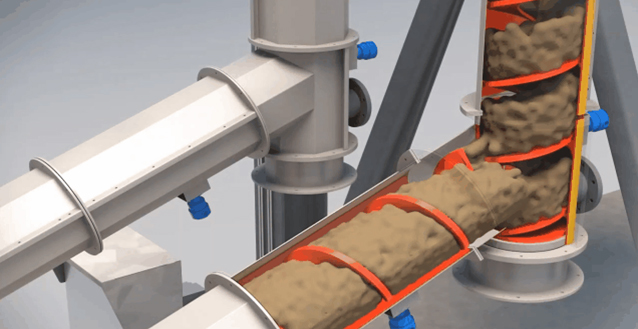

Pipe chain conveying

Generally, powder or small particle materials can be transported by gas transmission, spiral, chute, etc., but these transportation methods will cause certain environmental pollution, and pipe chain transportation can solve this problem.

The pipe chain conveying system is mainly composed of feed inlet, conveying pipe, discharge port, chain wheel, chain with disc, motor, etc.; in the closed pipeline, the circular disc is pulled by the chain, thus the animal feed is transported continuously.

The whole conveying line is composed of two conveying pipes, which form an interlinked circulation loop. At the turning point of the conveying pipe, the turning sprocket is set. The material is transported by the reversing device at right angle or other angles, and each conveyor can turn many times.

Therefore, the pipe chain transportation will not be restricted by the environment, can effectively avoid obstacles, and the conveying direction becomes very flexible.

Material transportation seems simple, but its role is very important. Therefore, various industries are constantly looking for the best way of transportation.